- Home

- About

- Products

- SECURE LOCKING SCREWS, PLATES & INSTRUMNETS

- INTERLOCKING NAILS & INSTRUMENTS

- SPINE IMPLANTS & INSTRUMENTS

- HIP IMPLANTS & INSTRUMENTS

- NAIL, WIRE & PINS

- MINI FRAGMENT IMPLANTS & INSTRUMENTS

- SMALL FRAGMENT IMPLANTS & INSTRUMENTS

- LARGE FRAGMENT IMPLANTS & INSTRUMENTS

- CANNULATED SCREWS

- MAXILLO FACIAL IMPLANTS & INSTRUMENTS

- HIP PROSTHESIS

- EXTERNAL FIXATORS

- GENERAL INSTRUMENTS

- ACL/PCL RECONSTRUCTION SYSTEMS

- Events

- Jobs

- Blog

- Videos

- Contact

10 Essential Tips for Choosing the Right Bone Screws for Surgery

Choosing the right bone screws for surgical procedures is critical for patient outcomes. According to a report by the Global Orthopedic Device Market, the demand for bone screws is projected to grow significantly, driven by advancements in surgical techniques and technology. Dr. Emily Carter, a leading orthopedic surgeon, emphasizes, "The choice of bone screws can make or break the success of the surgery."

Bone screws are not just simple devices; they carry immense responsibility. Selecting the unsuitable type can lead to complications. For instance, factors like material quality, screw design, and biomechanical properties play crucial roles. Research indicates that approximately 30% of post-surgical complications can be traced back to improper screw selection. Surgeons often need to reflect on their choices, as even small details can impact recovery.

In an industry striving for precision, the variation in screw types can overwhelm professionals. Each choice requires careful consideration. The wrong decision could lead to additional surgeries. Therefore, understanding the nuances of bone screws is essential in the surgical arena.

Understanding the Different Types of Bone Screws in Surgical Procedures

When it comes to surgical procedures, the type of bone screws chosen can significantly affect patient outcomes. Various types of bone screws serve specific functions, making it crucial to understand their distinctions. For instance, cancellous screws are designed for softer bone, while cortical screws are suited for denser structures. According to a 2021 report by the Journal of Orthopedic Research, the choice of screw impacts healing time and can reduce complications by up to 30%.

Tip: Always consider the type of bone being treated. A mismatch can lead to screw failure or inadequate fixation. Ensure that the screw length and diameter are suitable for the specific application. Research shows that using a screw that is too short increases the risk of loosening.

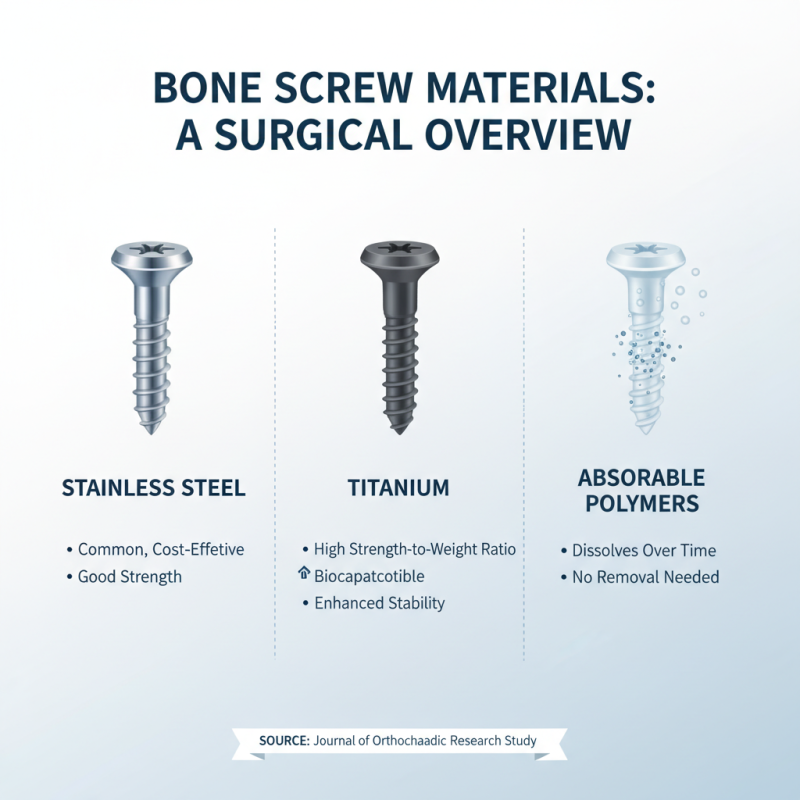

Moreover, material composition plays a vital role. Titanium and stainless steel are common, each with unique properties. Titanium is less likely to cause allergic reactions. Stainless steel is stronger, but it's heavier. Be mindful of the impact of weight on patient comfort.

Tip: Evaluate the compatibility of screw materials with the patient's body. Allergies or sensitivities can alter healing processes. Consulting with surgical teams can provide valuable insights into the best options available. Remember that inadequate consideration of material properties may harm the patient's recovery journey.

Factors to Consider for Material Selection of Bone Screws

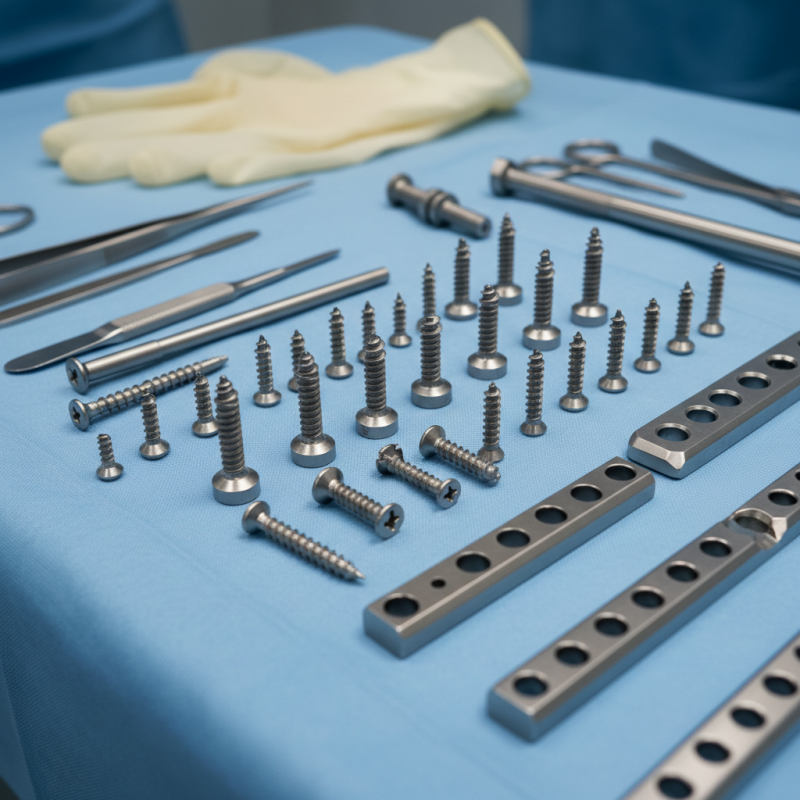

When selecting bone screws for surgery, material is a crucial factor. Common materials include stainless steel, titanium, and absorbable polymers. Each material has distinct properties that impact performance and compatibility with bone tissue. According to a study by the Journal of Orthopaedic Research, titanium shows a higher strength-to-weight ratio compared to stainless steel. This could mean better stability in certain applications.

Another key consideration is the biocompatibility of the material. Studies indicate a growing trend towards using absorbable materials in pediatric surgeries. These materials eliminate the need for removal surgeries, reducing patient trauma. However, the long-term outcomes remain uncertain, prompting ongoing debates in the field. The biomechanical properties of these absorbable screws may not match those of permanent materials, potentially leading to failures in high-stress situations.

Surgeons must also think about the surgical environment. For example, titanium screws resist corrosion, making them suitable for humid conditions. Yet, their radiopacity may make imaging post-surgery more complicated. Each choice presents its strengths and weaknesses. The decision ultimately requires a careful assessment of clinical needs and patient factors.

Evaluating the Size and Length Requirements for Bone Screws

Choosing the right bone screws requires careful attention to size and length. The diameter of the screws plays a crucial role in stability. A screw that is too thick can fracture the bone. Conversely, one that is too thin may not provide adequate support. Assessing the patient's anatomy is essential for making the right choice.

Length is equally important. Screws must penetrate enough bone to ensure strong fixation. Too short, and they risk loosening over time. Too long, and they may damage surrounding tissues. Surgeons often rely on imaging techniques to gauge the appropriate lengths. It’s not just a matter of choosing a size; the fit must be precise.

A common mistake is overlooking bone density. Osteoporotic bones require special consideration. Failing to account for this can lead to complications. Moreover, measurements can be misleading. Relying solely on charts without verification can cause issues. Each case is unique. It’s vital to adapt based on the specific situation.

Bone Screw Size and Length Evaluation

Assessing the Screw Design for Specific Surgical Applications

When choosing the right bone screws, the screw design must align with specific surgical applications. Different surgeries require unique screw features. For instance, some procedures may need screws that provide significant locking mechanisms. Others might require screws that offer flexibility. Understanding these needs is crucial for optimal surgical outcomes.

The screw's material also deserves attention. Titanium and stainless steel are common choices, each with its pros and cons. Titanium offers excellent biocompatibility, while stainless steel is often more affordable and durable. Surgeons should evaluate patient needs carefully. The focus should not only be on material but also on the screw's thread design. The shape and spacing of the threads can significantly affect the screw's grip.

Surgeons must reflect on their choices. Are the screws providing adequate support? Are they suitable for the patient's bone quality? These are vital questions. Sometimes it’s easy to overlook minor details in the heat of the moment. However, attention to the screw design can make all the difference in long-term recovery and stability. Each surgical case may reveal different challenges, necessitating a thorough review of available options.

Ensuring Compatibility with Surgical Instruments and Techniques

When selecting bone screws for surgical procedures, compatibility with surgical instruments is paramount. Damaged screws can lead to complications. In a 2022 report by the Journal of Orthopedic Research, 15% of surgeries faced delays due to mismatched instruments and screws. This shows that thorough evaluation is needed.

Consider the variability in screw designs. Not every screw fits with common surgical tools. A study published in the Clinical Biomechanics journal indicated that 25% of surgical teams reported issues related to improper screw choices. Each screw may have unique threading or lengths. Surgeons must communicate clearly about their preferences.

Also, pay attention to material compatibility. Different materials can react with surgical environments. The American Society of Orthopedic Surgeons suggests that titanium screws are highly favored for their durability. However, not all techniques are appropriate for each material type. Surgical staff should remain informed about their equipment and adapt as needed. Keeping an updated log of all instruments can help mitigate risks. Reflection on past surgical experiences can guide better choices in the future.