Orthopedic care has evolved significantly over the past few decades, offering patients advanced solutions for bone and joint disorders. Among these, hip implants have emerged as a critical component in restoring mobility and improving quality of life for patients suffering from hip injuries, arthritis, or degenerative joint diseases. Choosing global quality hip implants instruments in India ensures not only superior surgical outcomes but also long-term reliability and patient satisfaction.

The Importance of High-Quality Orthopaedic Implants

Orthopaedic implants play a pivotal role in modern surgical procedures. They are designed to replace or support damaged bones and joints, allowing patients to regain functionality and mobility. The global market has set stringent standards for quality, durability, and biocompatibility of these implants. By opting for hip implants instruments in India that meet international standards, surgeons can ensure safe and effective treatment.

High-quality orthopaedic implants, including spine implants, interlocking nails, and locking plates and screws, provide precise anatomical alignment, reduce complications, and promote faster recovery. Moreover, implants manufactured using advanced technologies and high-grade materials like titanium and stainless steel ensure long-term durability and resistance to wear.

Global Quality Hip Implants Instruments in India

India has emerged as a hub for manufacturing and exporting orthopaedic implants that meet global quality standards. Reputed manufacturers in India offer a wide range of products, including:

Hip Implants – Designed for total hip replacement (THR) and partial hip replacement procedures, these implants restore joint functionality and reduce pain.

Spine Implants – Including screws, rods, and cages, these implants support spinal fusion procedures and maintain spinal stability.

Interlocking Nails – Used primarily in long bone fractures like femur and tibia, these nails provide strong internal fixation and facilitate early mobility.

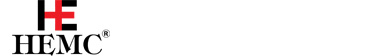

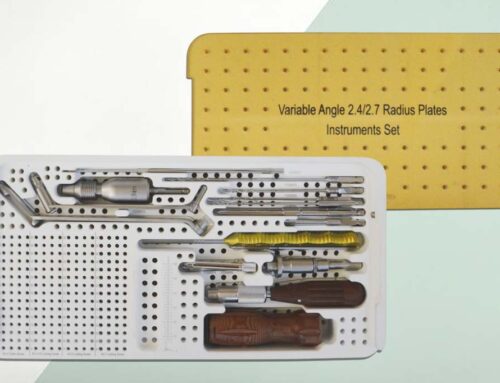

Locking Plates and Screws – Provide stable fixation in complex fractures, ensuring proper bone alignment and faster healing.

The adoption of advanced manufacturing processes, stringent quality control, and compliance with international standards (like ISO and CE certifications) make Indian orthopaedic implants instruments highly reliable and globally competitive.

Advantages of Using Indian Orthopaedic Implants

Cost-Effective Solutions

- Global quality hip implants instruments manufactured in India offer the advantage of affordability without compromising on quality. Hospitals and surgical centers can access high-grade implants at competitive prices, making advanced orthopedic care more accessible to a wider population.

Advanced Technology and Materials

- Leading Indian manufacturers utilize cutting-edge technologies such as CNC machining, precision casting, and additive manufacturing to produce implants with high accuracy. Using biocompatible materials like titanium alloys ensures implants are safe, durable, and resistant to corrosion.

Wide Range of Products

- From hip implants to spine implants, interlocking nails, and locking plates and screws, Indian manufacturers provide a comprehensive portfolio to meet the diverse requirements of orthopedic surgeons. This range ensures that healthcare providers can source multiple solutions from a single, trusted supplier.

Global Compliance and Certification

- Reputed manufacturers in India adhere to international quality standards, ensuring that their orthopaedic implants are CE and ISO certified. This guarantees patient safety and compliance with regulatory requirements in multiple countries.

Applications of Orthopaedic Implants in Hip and Bone Surgeries

- Hip implants instruments are commonly used in total hip replacement surgeries, which are recommended for patients with severe arthritis, fractures, or congenital hip deformities. The use of high-quality instruments ensures precise implant placement, reducing the risk of dislocation and improving long-term outcomes.

- Spine implants support procedures like spinal fusion and scoliosis correction. High-quality screws, rods, and cages provide stability and proper alignment, reducing post-operative complications.

- Interlocking nails are ideal for long bone fractures, such as femur and tibia. These nails offer internal fixation and allow early mobilization, which is crucial for faster recovery.

- Locking plates and screws are widely used in fracture management. They provide rigid fixation for complex fractures, minimize surgical complications, and support proper bone healing.

Choosing the Right Hip Implant Instruments

Selecting the right hip implant instruments is critical for successful orthopedic surgeries. Surgeons should consider the following factors:

- Material Quality – Titanium and cobalt-chromium alloys are preferred for their biocompatibility and strength.

- Design Accuracy – Anatomically designed implants ensure better fit, alignment, and range of motion.

- Sterilization and Safety – Instruments must comply with sterilization standards to prevent post-surgical infections.

- Manufacturer Reputation – Partnering with certified Indian manufacturers ensures adherence to global quality standards and reliable post-sales support.

The Role of Indian Manufacturers in Global Orthopaedics

Indian orthopaedic manufacturers have carved a niche in the global market by offering high-quality, cost-effective, and certified implants. By focusing on research, innovation, and international collaborations, they continue to raise the standards of orthopedic care. Many hospitals worldwide now rely on Indian orthopaedic implants, spine implants, interlocking nails, and locking plates and screws due to their reliability and competitive pricing.

Moreover, Indian manufacturers are committed to training surgeons on the proper use of implants and instruments, ensuring that healthcare providers maximize patient outcomes. Advanced packaging, timely delivery, and comprehensive after-sales service further enhance their credibility as a global supplier.

Conclusion

Ensuring the best treatment with global quality hip implants instruments in India is now more achievable than ever. With advancements in technology, stringent quality standards, and a wide range of products including orthopaedic implants, spine implants, interlocking nails, and locking plates and screws, Indian manufacturers provide solutions that rival international competitors.

Healthcare providers can now offer patients reliable, durable, and safe orthopedic solutions at competitive prices. By choosing trusted Indian manufacturers, surgeons can ensure precision, improved recovery, and long-term success in hip and orthopedic surgeries.

Investing in global quality hip implants instruments in India is not just a step towards better surgical outcomes, but also a commitment to affordable, world-class orthopedic care.

Leave A Comment