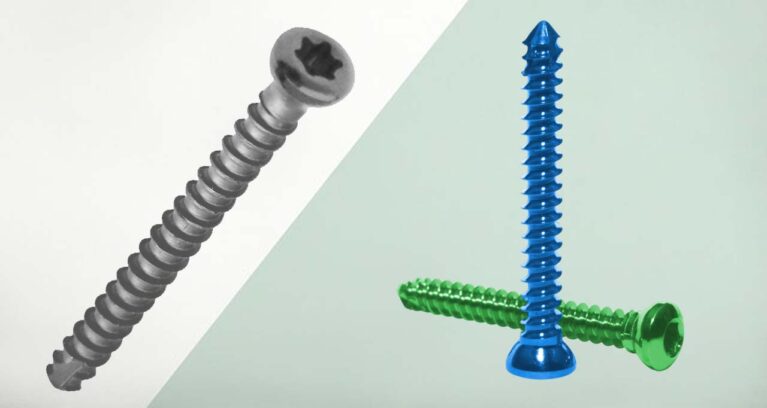

Cortical screws are a type of orthopedic screw designed to anchor implants to dense cortical bone, which forms the hard outer layer of bones. These screws are commonly used in trauma and orthopedic surgeries to fix fractures or attach plates to bones.

Key Characteristics of Cortical Screws:

Thread Design:

- Fine threads with a small pitch (distance between threads), allowing tight engagement with hard cortical bone.

- The threads usually span the entire shaft (fully threaded), but partially threaded versions are also available.

Diameter:

- Typically, smaller in diameter compared to cancellous screws (commonly 2.7 mm, 3.5 mm, 4.5 mm sizes).

Material:

- Made of stainless steel or titanium, depending on biocompatibility and strength needs.

Usage:

- Often used with bone plates, such as in fracture fixation of the radius, ulna, tibia, fibula, etc.

- Can also be used independently to compress fracture fragments (lag screw technique).

Functions:

- Secure fixation in cortical bone.

- Provide compression across fracture sites when used as lag screws.

- Help stabilize internal fixation systems (plates or rods).

Types of Cortical Screws

Cortical screws come in various types based on design, thread configuration, and usage. Here are the main types of cortical screws used in orthopedic procedures:

Fully Threaded Cortical Screws

- Threads run the entire length of the shaft.

- Commonly used to secure plates to bone or as positional screws.

- Provides uniform grip in both near and far cortices.

Partially Threaded Cortical Screws

- Threads only on the distal portion of the shaft.

- Designed to create interfragmentary compression—used as lag screws to compress bone fragments together.

Standard Cortical Screws

- Non-locking screws used with dynamic compression plates (DCPs) or reconstruction plates.

- Typically made of stainless steel or titanium.

- Sizes: 1.5 mm, 2.0 mm, 2.7 mm, 3.5 mm, and 4.5 mm.

Locking Cortical Screws

- Have threads on the head that lock into corresponding threaded holes in locking plates.

- Create a fixed-angle construct, offering more stability in osteoporotic or comminuted bone.

Self-tapping Cortical Screws

- Feature a cutting flute at the tip that eliminates the need for tapping before insertion.

- Speeds up the procedure and reduces the number of steps.

Self-drilling Cortical Screws

- Designed to drill and tap into bone without pre-drilling.

- Often used in smaller bones or in areas where quick application is essential.

Cannulated Cortical Screws

- Have a central hollow core to allow placement over a guide wire.

- Useful for minimally invasive or percutaneous fixation.

Benefits of cortical screws

Cortical screws offer several clinical and mechanical benefits in orthopedic and trauma surgery. Here’s a detailed breakdown of their benefits:

Strong Fixation in Dense Bone

- Designed specifically for cortical bone, which is dense and strong.

- Fine, closely spaced threads ensure maximum grip and minimize the risk of loosening.

- Ideal for diaphyseal regions (shaft of long bones) where cortical bone is predominant.

Versatility in Surgical Applications

- Used for a variety of purposes:

- Securing bone plates (DCP, LCP).

- Performing lag screw techniques for fragment compression.

- Stabilizing fractures independently.

- Can be used in both trauma fixation and elective orthopedic procedures.

Promotes Fracture Healing

- When used as lag screws, they provide interfragmentary compression, which promotes:

- Primary bone healing (direct bone remodeling).

- Stable fracture union with minimal callus formation.

Compatibility with Plate Systems

- Fully compatible with many internal fixation systems like:

- Dynamic Compression Plates (DCP)

- Limited Contact Dynamic Compression Plates (LC-DCP)

- Locking Compression Plates (LCP)

- Locking variants allow for angular stability, reducing reliance on bone quality alone.

Customization Options

- Available in various diameters and lengths (e.g., 2.7 mm, 3.5 mm, 4.5 mm), enabling customization for:

- Different bones (e.g., radius, tibia, femur).

- Varying fracture patterns and surgical needs.

Reduced Risk of Back-Out or Migration

- The fine threading and precise engagement in hard cortical bone help prevent screw loosening or migration over time.

- Especially beneficial in weight-bearing bones.

Durable and Biocompatible

- Made from materials like stainless steel or titanium, offering:

- Long-lasting durability.

- Corrosion resistance.

- Biocompatibility, reducing the risk of allergic or inflammatory reactions.

Cost-Effective and Widely Available

- Standard cortical screws are generally affordable, making them a go-to solution in many global healthcare settings.

- Available in reusable and single-use sterile options.